| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Xianheng

Model Number : Custom Made

Certification : ISO 9001:2015 SGS RoHS

Place of Origin : China Guangdong

MOQ : 1 pcs

Price : USD 0.1$-2$

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 10 SET per week

Delivery Time : 5-8 days

Packaging Details : Carton Wooden case

Material Capabilities : Stainless Steel,Aluminium,Copper,Brass

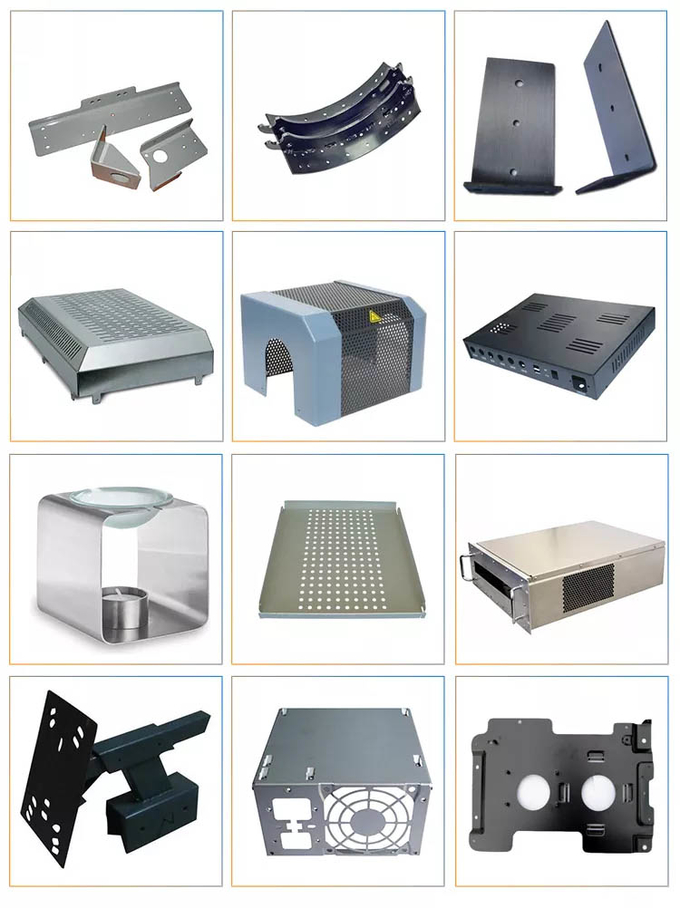

Products : Metal eauipment shell, Sheet Metal Cabinet Assembly Stamping Parts

Process : Metal casing,Metal sheets fabrication,Welding Cutting Punching Stamping

Application : Carbinet, parts:Cars, e-sports hotel, architecture, furniture,metal plastic parts

Tolerance : +/-0.02mm

MOQ : 1 Piece

OEM/ODM : Acceptable

Equipment : Laser Cutter, CNC Bending Machine, Stamping Machine, Weld

Surface treatment : Galvanized,Anodizing,Powder Coated,Chrome Plating,Nickel plating etc.

Craftsmanship : CNC stamping,CNC bending,Welding,Laser cutter, Stamping

Applications : Automotive,Medical,Telecom,Construction,machine etc

Keyword : Elctric Metal Eauipment shell, Sheet Metal Cabinet Assembly Stamping Parts

Inspection Tool : Measuring Tape, Caliper, R Gauge, X-Ray, Salt Spray

Package : Platic Bag ,Blister Box ,Tap Reel or as your required

Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery

Description of Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery

Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace, Defense, Automotive, and Industrial Machinery refers to high-precision metal enclosures manufactured through advanced CNC (Computer Numerical Control) turning and stamping processes. These cabinets are engineered to house sensitive electronics, control systems, and critical components, providing protection against environmental hazards (e.g., dust, moisture, chemicals), mechanical stress (e.g., vibration, impact), and unauthorized access. Designed for seamless integration with complex machinery, they meet the stringent demands of industries where reliability, durability, and precision are non-negotiable.

Specification of Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery

| CNC Capacity | ||||

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Centers | 40+ CNC Machines | ||

| CNC Turning | φ0.5 - φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm | ||

| CNC Machining | 1270×508×635 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |||

| Inspection Equipments | Measurement Instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |||

| Material Available | ||||

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, 17-4PH, etc. | |||

| Steel | Mild steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||

| Copper | C11000,C12000,C12000 C36000 etc. | |||

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||

| Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. | |||

| Surface Finishing | ||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Copper /Brass | Plastic Parts |

| Clear Anodized | Polishing | Zinc plating | Polishing | Painting |

| Color Anodized | Passivating | Oxide black | Passivation | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Galvanized | polishing |

| Chemical Film | Laser engraving | Chrome plating | Nickel Plating | Sandblast |

| Brushing | Carburized | Chrome plating | Laser engraving | |

| Polishing | Heat treatment | |||

| Chroming | Powder Coated | |||

Application Of Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery

1. Auto Components Hardware Parts Auto Parts

2. Communication Equipment

3. Industrial Equipment

4. Medical EquipmentsMechanical Parts

5. Ship Accessories

6. Electrical Equipment

7. Mechanical Equipment

Feature Of Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery

1. Good corrosion resistance

2. High strength and hardness

3. High thermal conductivity

4. Good finishing characteristics

Advantages

Unmatched Precision and Tolerance Control

CNC turning and stamping achieve ±0.005 mm (or tighter) dimensional accuracy, ensuring compatibility with high-performance systems in aerospace, defense, and medical applications.

Consistent quality across production runs minimizes rework and replacements, reducing material waste and budget overruns. For example, aerospace components often require tolerances within 0.001 mm, a standard easily met by CNC processes.

Superior Durability and Functional Performance

Metal cabinets are crafted from corrosion-resistant alloys (e.g., aluminum, stainless steel, or titanium) to withstand extreme temperatures, vibration, and chemical exposure.

Stamping processes create rigid, lightweight structures with reinforced joints, optimizing strength-to-weight ratios—critical for automotive and aerospace efficiency. For instance, an aluminum cabinet for an EV battery system can weigh 30% less than a steel equivalent while maintaining structural integrity.

Rapid Customization and Scalability

CNC technology enables fast prototyping and iterative design, allowing for tailored solutions like EMI/RFI shielding, conformal cooling channels, or modular assemblies.

Automated workflows support high-volume production (e.g., 1,000+ units/day) with minimal lead times, making it cost-effective for both low-volume specialty parts and large-scale deployments. A defense contractor, for example, can produce 500 missile guidance enclosures in a week with consistent quality.

Cost-Effective Production and Long-Term Savings

Reduced material waste and optimized tool paths lower per-unit costs, while precision stamping extends tool life by minimizing wear and tear.

Fully automated processes reduce labor costs, and human-machine interfaces are user-friendly, requiring minimal training. A study found that CNC machining can cut production costs by 20-30% compared to traditional methods for complex parts.

FAQ

Q: How can I customize my products ?

A: Please describe your project. Include the following information so that we can provide an accurate quote: Part Name, 3D CAD Drawing, Quantity, Material, Color, Finishing.

Q: How can I know my products going on ?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the production process.

Q: Can You sign a confidentiality greement ?

A: We can sign a confidentiality agreement according to your needs.

Q: What is your terms of payment ?

A: 30% in advance ,70% balance before shipment. Other terms negotiable.

Q: Are you a trading company or factory?

A: We are direct factory with 20 experienced engineers and more than 80 employees as well approximate 3,000 square meters workshop area.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length, Height, Width), CAD or 3D file will be made for you if placed order.

|

|

Precision-Made CNC Turning and Stamping Metal Cabinet Assembly for Aerospace Defense Automotive and Industrial Machinery Images |